CONVEYOR HW FOR METAL SHARK® BD Conveyor system HW

[button link=”https://drive.google.com/file/d/1wjvs2KFI53sP61JXj7DxrA6o_QDFk4pW/view?usp=sharing” target=”_blank” color=”default” shape=”rounded” size=”small” align=”left”]CATALOG[/button]

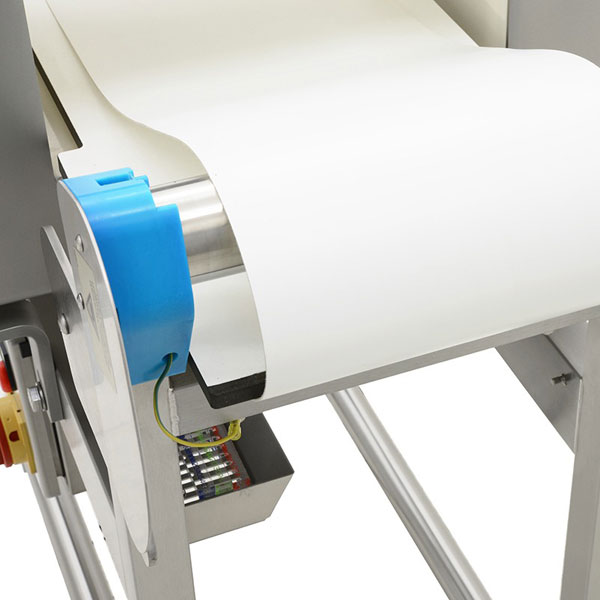

System solution consisting of metal detector METAL SHARK® BD and Conveyor HW

Disassembled in a few easy steps – ideal for daily hose cleaning

Removable PU belt is FDA compliant

Stable frame construction made of 100% stainless steel

Very cost-efficient and easy to integrate into existing conveyor lines

Function

The HW series conveyor belts are combined as standard with METAL SHARK® BD metal detectors and are mainly adapted to the requirements of the food industry.

The white PU belt is FDA compliant and can be removed in just a few steps. The belt and the stable stainless steel frame can be cleaned easily and quickly.

Specifications

| Frame | Stainless steel AISI 304 / ISO 1.4301, profiles closed on all sides, available with adjustable floor stands (standard) or castors |

| Enclosure rating | IP66 (NEMA4X) |

| Height | 825 mm ± 75 mm |

| Belt speed | 5-30 m/min (variable with STR/STL) |

| Engine | Drum motor, stainless steel |

| Belt control | Start/stop/reset |

| Product weight | 10 or 15 kg |

| Power supply | 220-240 VAC, 50-60 Hz, 1 Ph, 0.4 kW 110 VAC, 60 Hz, 1 Ph, 0.4 kW |

| Conformity | CE (Declaration of Conformity and Declaration of Manufacturer) |

| Model | Belt width (mm) | Length (mm) | Product weight (kg) | Aperture detector BD | |

| Height (mm) | Width (mm) | ||||

| HW 1000/075 | 250 | 1000 | 10 | 50 | 350 |

| HW 1000/100 | 250 | 1000 | 10 | 75 | 350 |

| HW 1000/125 | 250 | 1000 | 10 | 100 | 350 |

| HW 1000/150 | 250 | 1000 | 10 | 125 | 350 |

| HW 1000/175 | 250 | 1000 | 10 | 150 | 350 |

| HW 1200/050 | 350 | 1200 | 15 | 25 | 450 |

| HW 1200/075 | 350 | 1200 | 15 | 50 | 450 |

| HW 1200/100 | 350 | 1200 | 15 | 75 | 450 |

| HW 1200/125 | 350 | 1200 | 15 | 100 | 450 |

| HW 1200/150 | 350 | 1200 | 15 | 125 | 450 |

| HW 1200/175 | 350 | 1200 | 15 | 150 | 450 |

| HW 1200/200 | 350 | 1200 | 15 | 175 | 450 |

| HW 1200/225 | 350 | 1200 | 15 | 200 | 450 |

| HW 1200/250 | 350 | 1200 | 15 | 225 | 450 |

Sản phẩm tương tự

Reliably detects metals in free-falling goods

Simple assembly due to mounting frame and quick release rings

Highest sensitivity with 4-quadrant technology

Autocalibration and TeachAssistant for intuitive control and easy installation

Maintenance-free through automatic balance and calibration control

ATEX-version for use in explosion endangered environments

BRC-Kit option: Conformity with the Global Standard of the British Retail Consortium (BRC) for food safety

Function

The METAL SHARK® GF (Gravity Feed) is used for pipelines with free-falling products to detect metal contamination in continuously flowing granulates or powders such as sugar, flour, grain or even plastic granules.

The sensitive sensors detect the smallest metal contaminants, and fast-switching separation flaps discharge them directly from the product stream during ongoing production.

[button link=”https://drive.google.com/file/d/1CfN0n6N2gAYLPOIjpp5Q_ZFbII4yZMu7/view?usp=sharing” target=”_blank” color=”default” shape=”rounded” size=”small” align=”left”]CATALOG[/button]

Reliably detects metals in packaged and unpackaged products on conveyor belts

Removable sides make it particularly easy to install, ideal for conveyors that cannot be split

Highest sensitivity with 4-quadrant technology

Autocalibration and TeachAssistant for intuitive control and easy setup

Maintenance-free due to automatic balance and calibration control

Function

Metal detector METAL SHARK® TU is used in combination with conveyor belts or chutes when they cannot be divided or dismantled. The sidewalls of the TU can be removed so that the sensor plates can be easily pushed over and under the belt.

Thanks to its 4-quadrant technology, it detects magnetic and non-magnetic metal contaminants (iron, stainless steel, aluminum etc.) precisely and reliably. The robust stainless steel housing is easy to clean and robust and therefore suitable for many industries.

[button link=”https://drive.google.com/file/d/1b7OBWPwwl17y7OM3o7M1bFgPnmPcKDH9/view?usp=sharing” target=”_blank” color=”default” shape=”rounded” size=”small” align=”left”]CATALOG[/button]

Specially designed for the monitoring of wood, fibre boards or any wide but thin product

AutoSens technology for automatic adjustment of the sensitivity to the mat height

Maintenance-free with automatic balance and calibration control

Durable aluminium design: particularly robust and easy to clean

Highest sensitivity with 4-quadrant technology

Autocalibration and Teach Assistant for intuitive control and easy installation

Features

Aperture widths from 1 m to 5 m as a standard (further sizes on request)

Maximum search performance with hig-hest reliability in the entire detection area due to 4-quadrant technology

Simple setup with TeachAssistant

Easy to use with intuitive and multilingu-al menus

Memory for up to 250 products

4-level password system, automatic log out after time lapse

Documentation of all events and metal messages

Optional: Data transfer to USB interface or connection to the company network via SHARKNET® software

Extended temperature range down to -40°C with specially adapted sensor and specially equipped control unit (option)

Cyclical function monitoring with Performance Validation System (PVS)

Function

The METAL SHARK® BIG pba with rectangular opening at a rather low opening height is especially designed for monitoring fibre mats, MDF, OSC or chipboard as well as other panel materials.

The typical installation takes place around a conveyor belt with flat belt.

Using 3D detection technology, it detects magnetic and non-magnetic metal contaminants (iron, stainless steel, aluminium etc.) precisely and reliably even under difficult conditions.

Accessories & Extras

The METAL SHARK® BIG pba can be perfectly adapted to your production with various special designs and accessories.

Different temperature requirements are taken into account as well as complicated product requirements for metal detection.

[button link=”https://drive.google.com/file/d/17NfxByJyw3l43EjPV2d3Irh7nNGF2gFw/view?usp=sharing” target=”_blank” color=”default” shape=”rounded” size=”small” align=”left”]CATALOG[/button]

X-ray inspection for packaged food or non-food products

Detects high density materials like metal, ceramic, stone or plastic

Easy operation with autocalibration and clearly arranged functions on 17“ touchscreen

XIA software for instant analysis and detection with high accuracy and reliability

Construction is optimized for easy cleaning and maintenance

Features

Real time detection with coloured contamination analysis

Functions for masking of product parts for better detection of contamination

Autosaving of inspection data with time and date stamp

User-friendly operation in daily business with 255 pre-set products

USB and Ethernet for data transfer

Hygienic and easy-to-open product tunnel for easy maintenance and cleaning

Built-in remote control and maintenance

24 hours non-stop operation

TÜV-approved: reliable safety standard (TÜV certificate optional)

Function

The XRAY SHARK® XD47 is particularly suitable for packaged food or non-food products, for example in plastic packaging, jars, cartons and even metal foil or metal cans. Unwanted foreign objects such as metal, stones, ceramics or plastic with high density in the product are detected.

All devices are individually manufactured and can therefore be perfectly adapted to your existing production line and individual product requirements. XRAY SHARK® XD47-H2-E2-MEAT is already optimally adapted to the inspection of meat in standardised E2 crates as standard.

Description

Unwanted foreign bodies in food, medicines or other non-food products are a major problem. Many foreign objects such as plastic, ceramics or glass cannot be detected with a metal detector. CASSEL x-ray inspection systems offer the ideal solution for the protection of your products.

The XRAY SHARK® XD47 is already one of our larger devices and is particularly suitable for packaged food or non-food products with larger dimensions or in containers.

The device detects foreign objects such as metal, stone, ceramics, glass or plastic with high density in products in plastic packaging, jars, cartons and even metal foil or metal cans.

User-friendly operation:

The XRAY SHARK® XD47 x-ray units have a large 17″ colour touch screen and intuitive software that is easy to use. No special training is required to operate the x-ray unit.

Hygienic design:

The hygienic design of the XRAY SHARK® XD47 makes cleaning and maintenance easy. All components are clearly arranged and can be disassembled and reassembled for cleaning. The large maintenance doors allow product jams to be removed quickly. This minimizes downtime for your production line.

Real-time detection with coloured contamination analysis:

CASSEL x-ray inspection systems enable maximum sensitivity in foreign object detection. Contaminated products are detected in real time and can be sorted out. The contamination is highlighted in colour on the touch screen of the x-ray unit.

Masking functions:

The sophisticated XIA 3 software allows to mask certain parts of the product. This is particularly useful for packaged products where the actual packaging should not be examined as a foreign object. The masking function prevents products from being ejected unnecessarily.

24 hours non-stop operation:

High-quality components and advanced technology enable non-stop operation, 24 hours a day, 7 days a week.

Reliable German safety standard – TÜV approved:

The immaculate design offers the quality-conscious manufacturer the highest level of safety and comfort for daily operation. The radiation leakage amounts to 3 µSv/h or less and can be TÜV -approved.

Ethernet and USB:

Connect our x-ray systems to your network. CASSEL x-ray systems are equipped with USB and Ethernet interfaces as standard.

Automatic storage of inspection data with time / date stamp:

All XRAY SHARK® units have an automatic storage function. Data can be stored for all inspected products or only for contaminated products. All data are provided with a time and date stamp. So you can easily check and evaluate these data.

Built-in remote control and maintenance:

All CASSEL x-ray systems can be controlled or maintained from a PC. This allows you to monitor the inspection performance from the office. If it is necessary for an expert to check and adjust the unit settings, this can also be easily done online. Call us and our qualified technicians will help you with any questions you may have, no matter where your x-ray unit is located. This will save you expensive travel expenses and help you find quick solutions.

Đánh giá

Chưa có đánh giá nào.