CONVEYOR HW FOR METAL SHARK® BD Conveyor system HW

[button link=”https://drive.google.com/file/d/1wjvs2KFI53sP61JXj7DxrA6o_QDFk4pW/view?usp=sharing” target=”_blank” color=”default” shape=”rounded” size=”small” align=”left”]CATALOG[/button]

System solution consisting of metal detector METAL SHARK® BD and Conveyor HW

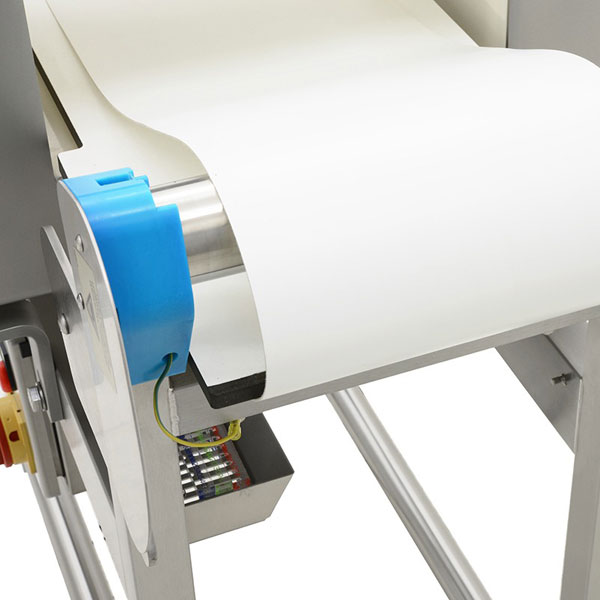

Disassembled in a few easy steps – ideal for daily hose cleaning

Removable PU belt is FDA compliant

Stable frame construction made of 100% stainless steel

Very cost-efficient and easy to integrate into existing conveyor lines

Function

The HW series conveyor belts are combined as standard with METAL SHARK® BD metal detectors and are mainly adapted to the requirements of the food industry.

The white PU belt is FDA compliant and can be removed in just a few steps. The belt and the stable stainless steel frame can be cleaned easily and quickly.

Specifications

| Frame | Stainless steel AISI 304 / ISO 1.4301, profiles closed on all sides, available with adjustable floor stands (standard) or castors |

| Enclosure rating | IP66 (NEMA4X) |

| Height | 825 mm ± 75 mm |

| Belt speed | 5-30 m/min (variable with STR/STL) |

| Engine | Drum motor, stainless steel |

| Belt control | Start/stop/reset |

| Product weight | 10 or 15 kg |

| Power supply | 220-240 VAC, 50-60 Hz, 1 Ph, 0.4 kW 110 VAC, 60 Hz, 1 Ph, 0.4 kW |

| Conformity | CE (Declaration of Conformity and Declaration of Manufacturer) |

| Model | Belt width (mm) | Length (mm) | Product weight (kg) | Aperture detector BD | |

| Height (mm) | Width (mm) | ||||

| HW 1000/075 | 250 | 1000 | 10 | 50 | 350 |

| HW 1000/100 | 250 | 1000 | 10 | 75 | 350 |

| HW 1000/125 | 250 | 1000 | 10 | 100 | 350 |

| HW 1000/150 | 250 | 1000 | 10 | 125 | 350 |

| HW 1000/175 | 250 | 1000 | 10 | 150 | 350 |

| HW 1200/050 | 350 | 1200 | 15 | 25 | 450 |

| HW 1200/075 | 350 | 1200 | 15 | 50 | 450 |

| HW 1200/100 | 350 | 1200 | 15 | 75 | 450 |

| HW 1200/125 | 350 | 1200 | 15 | 100 | 450 |

| HW 1200/150 | 350 | 1200 | 15 | 125 | 450 |

| HW 1200/175 | 350 | 1200 | 15 | 150 | 450 |

| HW 1200/200 | 350 | 1200 | 15 | 175 | 450 |

| HW 1200/225 | 350 | 1200 | 15 | 200 | 450 |

| HW 1200/250 | 350 | 1200 | 15 | 225 | 450 |

Sản phẩm tương tự

[button link=”https://drive.google.com/file/d/1sv7Lc5iq67BWyie6fm4VeOwYEc1Sxboo/view?usp=sharing” target=”_blank” color=”default” shape=”rounded” size=”small” align=”left”]CATALOG[/button]

Reliably detects metals in packaged and unpackaged products on conveyor belts

High sensitivity in dry, moist, salty or frozen goods with 3D detection

Easy setup and intuitive operation due to auto-calibration and TeachAssistant

Maintenance-free design with the automatic and continuous calibration of detector coils

BRC-Kit option: Conformity with the Global Standard of the British Retail Consortium (BRC) for food safety

Special models: UltraSens for even better sensitivity or Twinhead model to overcome orientation effects

[button link=”https://drive.google.com/file/d/1CfN0n6N2gAYLPOIjpp5Q_ZFbII4yZMu7/view?usp=sharing” target=”_blank” color=”default” shape=”rounded” size=”small” align=”left”]CATALOG[/button]

Reliably detects metals in packaged and unpackaged products on conveyor belts

Removable sides make it particularly easy to install, ideal for conveyors that cannot be split

Highest sensitivity with 4-quadrant technology

Autocalibration and TeachAssistant for intuitive control and easy setup

Maintenance-free due to automatic balance and calibration control

Function

Metal detector METAL SHARK® TU is used in combination with conveyor belts or chutes when they cannot be divided or dismantled. The sidewalls of the TU can be removed so that the sensor plates can be easily pushed over and under the belt.

Thanks to its 4-quadrant technology, it detects magnetic and non-magnetic metal contaminants (iron, stainless steel, aluminum etc.) precisely and reliably. The robust stainless steel housing is easy to clean and robust and therefore suitable for many industries.

[button link=”https://drive.google.com/file/d/1b7OBWPwwl17y7OM3o7M1bFgPnmPcKDH9/view?usp=sharing” target=”_blank” color=”default” shape=”rounded” size=”small” align=”left”]CATALOG[/button]

Specially designed for the monitoring of wood, fibre boards or any wide but thin product

AutoSens technology for automatic adjustment of the sensitivity to the mat height

Maintenance-free with automatic balance and calibration control

Durable aluminium design: particularly robust and easy to clean

Highest sensitivity with 4-quadrant technology

Autocalibration and Teach Assistant for intuitive control and easy installation

Features

Aperture widths from 1 m to 5 m as a standard (further sizes on request)

Maximum search performance with hig-hest reliability in the entire detection area due to 4-quadrant technology

Simple setup with TeachAssistant

Easy to use with intuitive and multilingu-al menus

Memory for up to 250 products

4-level password system, automatic log out after time lapse

Documentation of all events and metal messages

Optional: Data transfer to USB interface or connection to the company network via SHARKNET® software

Extended temperature range down to -40°C with specially adapted sensor and specially equipped control unit (option)

Cyclical function monitoring with Performance Validation System (PVS)

Function

The METAL SHARK® BIG pba with rectangular opening at a rather low opening height is especially designed for monitoring fibre mats, MDF, OSC or chipboard as well as other panel materials.

The typical installation takes place around a conveyor belt with flat belt.

Using 3D detection technology, it detects magnetic and non-magnetic metal contaminants (iron, stainless steel, aluminium etc.) precisely and reliably even under difficult conditions.

Accessories & Extras

The METAL SHARK® BIG pba can be perfectly adapted to your production with various special designs and accessories.

Different temperature requirements are taken into account as well as complicated product requirements for metal detection.

[button link=”https://drive.google.com/file/d/1av4SiQqk3SbIiPmpV_eQM_-SdkUCAEfJ/view?usp=sharing” target=”_blank” color=”default” shape=”rounded” size=”small” align=”left”]CATALOG[/button]

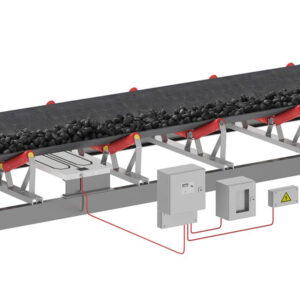

Monitors bulk materials in the mining and building materials industry

Self-adjusting and extremely easy to install

High-quality components ensure reliability and long service life

Detects ferrous and non-ferrous metals, iron oxide and ore are ignored

Probe and amplifier are immune to vibration and resistant to weather, dirt and stone chips

Sturdy aluminium design: particularly robust and easy to clean

Features

High sensitivity (M6 nuts) at belt speed of 0.1 – 4 m/s

Very simple operation

Can be used near frequency converters, only 1 m minimum distance between probe and motors or magnets

Monitoring and display of internal para-meters

Optional: Realization as tandem for higher debris heights

Optional: complete blanking of magneti-te Fe304

Function

The SQ and SQTA metal detectors offer good metal sensitivity for monitoring bulk materials in the mining and construction industry.

They are extremely durable, insensitive to vibrations and resistant to weather, dirt or stone chips. They are easy to install, handle and maintain.

Both are available for belt widths from 500 mm to 1,200 mm. At a belt speed of 0.1 – 4.0 m/s they can easily detect metal parts of the size of about M6 nuts and larger.

For a higher belt speed (M10 nuts) at a belt speed of max. 4.0 m/s we recommend the metal detectors SQ and SQTA.

Đánh giá

Chưa có đánh giá nào.