METAL DETECTION FOR FREE-FALLING PRODUCTS METAL SHARK® GF

Reliably detects metals in free-falling goods

Simple assembly due to mounting frame and quick release rings

Highest sensitivity with 4-quadrant technology

Autocalibration and TeachAssistant for intuitive control and easy installation

Maintenance-free through automatic balance and calibration control

ATEX-version for use in explosion endangered environments

BRC-Kit option: Conformity with the Global Standard of the British Retail Consortium (BRC) for food safety

Function

The METAL SHARK® GF (Gravity Feed) is used for pipelines with free-falling products to detect metal contamination in continuously flowing granulates or powders such as sugar, flour, grain or even plastic granules.

The sensitive sensors detect the smallest metal contaminants, and fast-switching separation flaps discharge them directly from the product stream during ongoing production.

Specifications

| Electronics | Digital signal processor, digital frequency generation, digital balance control, automatic calibration, digital noise filters, integrated flexible control functions |

| Input | 2 analog 0…10 V DC (option: 4-20 mA) 8 freely configurable 24 V DC signals, e.g. for reject confirmation |

| Output | 2 floating: “error” and “metal” 8 freely configurable 24 V DC signals, e.g. for metal or acoustic alarm |

| Inspection method | High-frequency magnetic field, multi-channel operation, symmetrical receiver coils |

| Metal detection | Ferrous, non-ferrous (e.g. aluminum or copper) And stainless steel |

| Product compensation | Memory for up to 250 products, automatic product compensation, with TeachAssistant |

| Enclosure rating | IP65 (optionally IP66) |

| Environmental conditions for controller | -30°C to +40°C / -22°F to 104°F, UL version: -20°C to +40°C / -4°F to 104°F, rel. humidity 20% up to 90% (non-condensing) Option: -40°C / -40°F or +55°C / 131°F |

| Environmental conditions for sensor | -30°C to +60°C / -22°F to 140°F Option: up to +90° C / 194°F |

| Temperature of goods inspected | Standard: -30°C up to 55°C / -22°F up to 131°F Option: -40°C / -40°F or up to 120°C / 248°F or up to 180°C / 356°F |

| Power supply | One phase 110-230 V AC, typ. consumption 20 W (max. 60 W) |

| Interface | RS232, provides documentation according to HACCP- and IFS-standard, USB- or ethernet option |

| Maintenance | Maintenance-free, self-calibrating sensors |

| Diagnostics | Integrated diagnostic software, automatic self-test |

| SHARKNET® | The SHARKNET® software connects METAL SHARK® metal detectors with a central computer, providing centralized storage of all operating data plus batch and alarm documentation for HACCP and IFS compliance. |

| BRC-Kit | BRC-Kit for a fail-safe system according to the guidelines of the British Retail Consortium with metal detection alarm, product counter, product jam monitoring, required covers, rejection system as well as monitoring of container (container full), air pressure of the reject system and reject functionality. |

| High-temperature extension for product | Product temperature up to max. +120°C, with this option the sensor has protection class IP54. |

| LPW/HPW | Increase of the IP protection class by adapting the sensor seal, installing additional seals and a double housing for the control electronics. |

| Signaling devices (optical/acoustic) | Stacking lights and signal horns/sirens available in different versions and IP protection classes. |

| ATEX version | Version for use in potentially explosive environments possible, ATEX zone 22. |

| Compressed air monitoring | Reports an error if the air pressure is too low for the functionality of the reject flaps. |

| Reject monitoring | Warns if the reject flap has not switched correctly after metal detection. |

| Flap position monitoring | Monitors the flaps for complete switching to the good or not good position. |

| Check & Catch | Material for simple functional testing, consisting of an insertion flap, through which spherical test specimens can be inserted into the pipeline, and a catchment grille for the test specimen including removal flap. |

| Autotest | Functional test that does not require opening the product pipelines: Test pieces (FE/NFE/VA) are moved with compressed air through a separate test tube. The control unit indicates which sphere sizes are to be tested. Incl. push button for FE, NFE and VA testing, pneumatic valve, test specimen. |

| Test balls | Test balls, diameter 25 mm made of plastic POM, with an embedded metal ball made of iron, brass and stainless steel, certified ball size, metal type and certificate number are embedded in the test ball. |

| Performance Verification Certificate | Issue of a Performance Verification Certificate (proof of functionality for audits) by CASSEL service technicians, e.g. during commissioning or maintenance. |

Sản phẩm tương tự

[button link=”https://drive.google.com/file/d/1AKd8ERvxZCLhwYOpQy1yeVZF2EPBv6rl/view?usp=sharing” target=”_blank” color=”default” shape=”rounded” size=”small” align=”left”]CATALOG[/button]

Reliably finds metal contaminants in sausage meat

Easy to integrate into all common piping systems

Stainless steel housing and frame are robust and easy to clean – ideal for the meat industry

Highest sensitivity with 4-quadrant technology

Autocalibration and Teach Assistant for intuitive control and easy installation

for use with twist-off devices, for clippers please use the IN Meat

Features

Maximum detection performance with the highest reliability in the entire detection area due to 4-quadrant technology

Simple setup with Teach Assistant

Storage spaces for up to 250 products

Easy to use with intuitive and multilingual menus

4-level password system, automatic log out after time lapse

Easy to fit into common pipelines

CIP-fähig (Cleaning In Place)

Documentation of all events and metal messages

IFS and HACCP reports available on the display at the touch of a button

Optional: Data transfer to USB interface or connection to the company network via SHARKNET® software

Cyclical function monitoring with Performance Validation System (PVS)

Function

Compact metal detector for sausage filling machines and sausage meat with the mobile base frame on wheels. The stand with integrated gas spring offers easy height adjustment from 85 to 120 cm height.

The METAL SHARK® INA Meat can be used universally with twisting devices and automatic clip machines. In the twist-off mode, the foreign device cable is simply plugged into the foreign device socket on the filling machine. For automatic clip machines or automatic hanging lines, the foreign device cable is inserted into the existing cable between the filling machine and the clip or hanging machine. Plug and socket types are supplied to match the filling machine type.

The device is easy to clean and complies with the FDA standard.

[button link=”https://drive.google.com/file/d/1gaUf4cFS6nUZ-sBRvoTbIiyOUGSPR3Tg/view?usp=sharing” target=”_blank” color=”default” shape=”rounded” size=”small” align=”left”]CATALOG[/button]

Reliably detects metal contaminants in tablets and capsules

IQ, OQ, PQ qualification certificates are delivered directly, SQ also possible on request

Ejection with pendulum bell ensures that products are not damaged or jammed

Mobile and height adjustable, dismountable without tools for cleaning

Intuitive control, autocalibration and Teach Assistant

Features

Maximum detection performance with highest reliability in the entire detection area due to 4-quadrant technology

Simple setup with Teach Assistant

Memory spaces for up to 250 products

Easy to use with intuitive and multilingual menus

4-level password system, automatic log out after time lapse

Documentation of all events and metal messages

IFS and HACCP reports available on the display at the touch of a button

Optional: Data transfer to USB interface or connection to the company network via SHARKNET® software

Cyclical function monitoring with Performance Validation System (PVS)

Function

The METAL SHARK® PH is typically used at the outlet of tablet presses. It offers the highest metal sensitivity in detecting magnetic and non-magnetic metals.

The tablets fall through the metal detector. The ejection flap arranged downstream separates tablets with the smallest metal contaminants from the product stream.

The high-quality construction is maintenance-free. For cleaning, all parts in contact with the product can be disassembled without tools.

[button link=”https://drive.google.com/file/d/1R13G-pezDuiVPu_ybIMzoqdrX2Sm22sP/view?usp=sharing” target=”_blank” color=”default” shape=”rounded” size=”small” align=”left”]CATALOG[/button]

Reliably detects metals in raw or frozen meat in standardized E2 boxes

Especially high sensitivity with moist or frozen products with 3D detection

Easy setup and intuitive operation with Autocalibration and TeachAssistant

Maintenance-free design with automatic and continuous calibration of detector coils

BRC-Kit option: Conformity with the Global Standard of the British Retail Consortium (BRC) for food safety

[button link=”https://drive.google.com/file/d/1VsV1-_LD80DdyLconHkAk96eVwsQMIPo/view?usp=sharing” target=”_blank” color=”default” shape=”rounded” size=”small” align=”left”]CATALOG[/button]

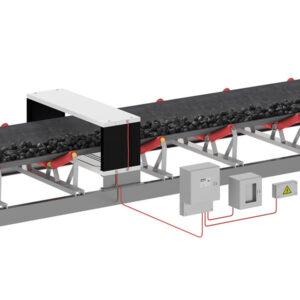

Monitors bulk materials in the building materials industry or mining

Self-adjusting and extremely easy to install

High-quality components ensure reliability and long service life

Detects ferrous and non-ferrous metals, iron oxide and ore are ignored

Probe and amplifier are immune to vibration and resistant to weather, dirt and stone chips

Particularly robust and easy to clean

Features

Good sensitivity (M10 nuts) at belt speed of 0.3 – 6 m/s

Very simple operation

Can be used close to frequency conver-ters, only 2 m minimum distance between probe and motors or magnets

Belt widths from 500 mm to 2,000 mm

Monitoring and display of internal para-meters

Optional: Realization as tandem for higher debris heights

Optional: complete suppression of magnetite Fe3O4

Function

The QLC and QLCTA metal detectors offer good metal sensitivity for monitoring bulk materials in the mining and construction materials industry.

At a belt speed of 0.3 – 6.0 m/s they easily detect metal parts of the size of about M10 nuts and larger.

For higher sensitivity (M6 nuts) at a belt speed of max. 4.0 m/s we recommend the metal detectors SQ and SQTA.

Đánh giá

Chưa có đánh giá nào.