METAL DETECTOR FOR LARGE PRODUCTS METAL SHARK® BIG

[button link=”https://drive.google.com/file/d/1vNrtKa6nE96FePk8Lai_RDHN4LDM0NyC/view?usp=sharing” target=”_blank” color=”default” shape=”rounded” size=”small” align=”left”]CATALOG[/button]

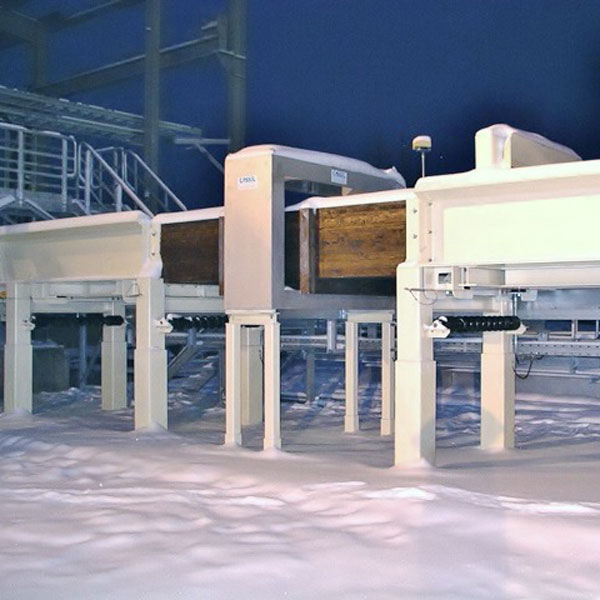

Sturdy aluminium design – particularly robust and weatherproof with short metal-free zone

Ideal protection for hackers and OSB flakers

High search performance and noise immunity through 4-quadrant technology, even better with Power Drive option

Maintenance-free: automatic calibration and automatic balance control

Easy installation and intuitive operation

Remote control and remote maintenance (option SHARKNET®) with documentation of all settings, metal messages etc.

Features

Aperture width standard up to 2 m x 1.6 m (other sizes on request)

Maximum detection performance with highest reliability in the entire detection area due to 4-quadrant technology

Easy setup with TeachAssistant

Easy to use with intuitive and multilingual menus

Memory for up to 250 products

Documentation of all events and metal messages

Remote control and remote maintenance via the company network using SHARKNET® software (option)

Extended temperature range down to -40°C / -40°F with specially adapted sensor and specially equipped control unit (option)

4-level password system, automatic logoff after time lapseFunction

The METAL SHARK® BIG with rectangular opening is specially designed for large products such as logs, bales or recycled wood. It detects iron, stainless steel, aluminium etc. precisely and reliably even under difficult conditions.

Thanks to its robust design, it is particularly suitable for industrial use on rough terrain. The typical installation is in a trough conveyor with flat belt, or in a specially prepared vibratory conveyor.

Accessories & Extras

The METAL SHARK® BIG can be perfectly adapted to your production with various special designs and accessories.

Different temperature requirements are taken into account as well as complicated product requirements for metal detection.

| Electronics | Digital signal processor, digital frequency generation, digital balance control, automatic calibration, digital noise filters, integrated flexible control functions |

| Input | 2 analog 0…10 V DC (option: 4-20 mA) 8 freely configurable 24 V DC signals, e.g. for encoders, product recognition, buttons |

| Output | 2 floating: “error” and “metal” 8 freely configurable 24 V DC signals, e.g. solenoid valve, optical/acoustic alarm |

| Inspection method | High-frequency magnetic field, multi-channel operation, balanced receiver coils |

| Metal detection | Ferrous, non-ferrous (e.g. tombac, brass, bronze, aluminium, lead etc.) and stainless steel |

| Product compensation | 250 memory locations, automatic product compensation, with TeachAssistant |

| Enclosure rating | IP 65 |

| Environmental conditions | -30°C to +40°C / -22°F to +104°F (UL version: -20°C to +40°C / -4°F to +104°F) option: to -40°C / -40°F or +55°C / +131°F, rel. humidity 20% to 90% non-condensing; >95% relative humidity (condensing) with closed switch cabinet |

| Product Temerature | up to 70°C / 158°F |

| Power Supply | 1 phase 110-230 V AC +/- 5% 20 W typ. (60 W max.) |

| Interface | RS232, LAN (optional, for SHARKNET®), USB (optional) |

| Maintenance | Maintenance-free, sensors calibrate themselves |

| Diagnostics | Integrated diagnostic software, automatic self-test |

| Fast Power Drive (FPD) | Improves metal detection and reliability in industrial environments that do not meet electromagnetic compatibility standards, various IP protection classes possible, ATEX Zone 22 possible. |

| SHARKNET® | The SHARKNET® software connects METAL SHARK® metal detectors to a central computer and offers central storage of all operating data as well as batch and alarm documentation and remote control and remote maintenance from a PC. |

| Temperature extension (cold) | Temperature range extended to -40°C / -40°F, resin seals remain elastic at low temperatures. Special insulation, heated enclosure and other features. |

| Temperature extension (hot) | Temperature range extended to +55°C / +131°F, adapted enclosure, additional thermal insulation, replaceable filter fan, heat exchanger and/or active cooling units. |

| Signalling devices (optical/acoustic) | Stacking lights and signal horns/sirens available in different versions and IP protection classes. |

Sản phẩm tương tự

[button link=”#” target=”_blank” color=”default” shape=”rounded” size=”small” align=”left”]Replace This Text[/button]

Modular conveyor HQ – optimally adapted to use with metal detector METAL SHARK® BD

100% stainless steel – stable construction and easy to clean

Different belt types and various ejection systems for every application, FDA compliant and heat resistant up to 120° C

Accessories such as railing, lights, covers, light sensors can be added individually

BRC-Kit: Conformity with all current standards for machines in the food industry

Function

The HQ conveyor belts are combined with METAL SHARK® BD metal detectors and are mainly adapted to the requirements of the food industry.

The white PU belt is FDA compliant and can be removed in just a few steps. The belt and the stable stainless steel frame can be cleaned easily and quickly and thoroughly.

HQ is a modular system witk a huge variaty of belt types an sizes, rejection systems, railings or coverages.

[button link=”https://drive.google.com/file/d/1wjvs2KFI53sP61JXj7DxrA6o_QDFk4pW/view?usp=sharing” target=”_blank” color=”default” shape=”rounded” size=”small” align=”left”]CATALOG[/button]

System solution consisting of metal detector METAL SHARK® BD and Conveyor HW

Disassembled in a few easy steps – ideal for daily hose cleaning

Removable PU belt is FDA compliant

Stable frame construction made of 100% stainless steel

Very cost-efficient and easy to integrate into existing conveyor lines

Function

The HW series conveyor belts are combined as standard with METAL SHARK® BD metal detectors and are mainly adapted to the requirements of the food industry.

The white PU belt is FDA compliant and can be removed in just a few steps. The belt and the stable stainless steel frame can be cleaned easily and quickly.

[button link=”https://drive.google.com/file/d/1VsV1-_LD80DdyLconHkAk96eVwsQMIPo/view?usp=sharing” target=”_blank” color=”default” shape=”rounded” size=”small” align=”left”]CATALOG[/button]

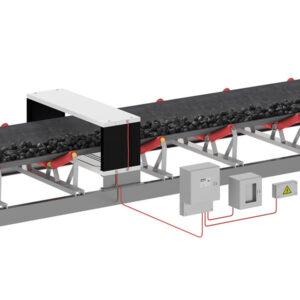

Monitors bulk materials in the building materials industry or mining

Self-adjusting and extremely easy to install

High-quality components ensure reliability and long service life

Detects ferrous and non-ferrous metals, iron oxide and ore are ignored

Probe and amplifier are immune to vibration and resistant to weather, dirt and stone chips

Particularly robust and easy to clean

Features

Good sensitivity (M10 nuts) at belt speed of 0.3 – 6 m/s

Very simple operation

Can be used close to frequency conver-ters, only 2 m minimum distance between probe and motors or magnets

Belt widths from 500 mm to 2,000 mm

Monitoring and display of internal para-meters

Optional: Realization as tandem for higher debris heights

Optional: complete suppression of magnetite Fe3O4

Function

The QLC and QLCTA metal detectors offer good metal sensitivity for monitoring bulk materials in the mining and construction materials industry.

At a belt speed of 0.3 – 6.0 m/s they easily detect metal parts of the size of about M10 nuts and larger.

For higher sensitivity (M6 nuts) at a belt speed of max. 4.0 m/s we recommend the metal detectors SQ and SQTA.

[button link=”https://drive.google.com/file/d/1b7OBWPwwl17y7OM3o7M1bFgPnmPcKDH9/view?usp=sharing” target=”_blank” color=”default” shape=”rounded” size=”small” align=”left”]CATALOG[/button]

Specially designed for the monitoring of wood, fibre boards or any wide but thin product

AutoSens technology for automatic adjustment of the sensitivity to the mat height

Maintenance-free with automatic balance and calibration control

Durable aluminium design: particularly robust and easy to clean

Highest sensitivity with 4-quadrant technology

Autocalibration and Teach Assistant for intuitive control and easy installation

Features

Aperture widths from 1 m to 5 m as a standard (further sizes on request)

Maximum search performance with hig-hest reliability in the entire detection area due to 4-quadrant technology

Simple setup with TeachAssistant

Easy to use with intuitive and multilingu-al menus

Memory for up to 250 products

4-level password system, automatic log out after time lapse

Documentation of all events and metal messages

Optional: Data transfer to USB interface or connection to the company network via SHARKNET® software

Extended temperature range down to -40°C with specially adapted sensor and specially equipped control unit (option)

Cyclical function monitoring with Performance Validation System (PVS)

Function

The METAL SHARK® BIG pba with rectangular opening at a rather low opening height is especially designed for monitoring fibre mats, MDF, OSC or chipboard as well as other panel materials.

The typical installation takes place around a conveyor belt with flat belt.

Using 3D detection technology, it detects magnetic and non-magnetic metal contaminants (iron, stainless steel, aluminium etc.) precisely and reliably even under difficult conditions.

Accessories & Extras

The METAL SHARK® BIG pba can be perfectly adapted to your production with various special designs and accessories.

Different temperature requirements are taken into account as well as complicated product requirements for metal detection.

Đánh giá

Chưa có đánh giá nào.