X-RAY INSPECTION SYSTEM FOR PACKAGED PRODUCTS XRAY SHARK® XD80-H2

[button link=”https://drive.google.com/file/d/1TidUSvegnWytqIKKbYJJkSHe1gRNZQ0k/view?usp=sharing” target=”_blank” color=”default” shape=”rounded” size=”small” align=”left”]CATALOG[/button]

X-ray inspection for packaged food or non-food products

Detects high density materials like metal, ceramic, stone or plastic

Easy operation with autocalibration and clearly arranged functions on 17“ touchscreen

XIA software for instant analysis and detection with high accuracy and reliability

Single or dual beam for optimized inspection of different product sizes and materials

Features

Real time detection with coloured contamination analysis

Functions for masking of product parts for better detection of contamination

Autosaving of inspection data with time and date stamp

User-friendly operation in daily business with 255 pre-set products

USB and Ethernet for data transfer to PC or memory stick

Single beam or dual beam available

Hygienic and easy to open product tunnel for easy cleaning and maintenance

Built-in remote control and maintenance

24 hours non-stop operation

Reliable German safety standard – TÜV-certificate available

Function

The XD80 is particularly suitable for packaged food or non-food products, for example in plastic packaging, jars, cartons and even metal foil or metal cans. Unwanted foreign objects such as metal, stones, ceramics or plastic with high density in the product are detected.

The hygienic design allows easy cleaning and maintenance of the device. This makes the XD80 particularly suitable for all companies and industries that have to ensure high hygiene standards.

Specifications

| Model | XD80-H2 (former XBD85+) |

|

| X-ray source | Dual beam x-ray generator with max. 80kV (2x480W), variable in voltage + current | |

| Radiation leakage | 3 µSv/h or less, at using all safety devices | |

| Safety | X-ray protective curtains (lead-free) – quickly detachable, magnetic safety switches at cabinet doors and tunnel hatches, emergency stop push button, emergency stop in/out interfaces to safety circuits of production line, X-ray off key switch, PILZ safety circuit | |

| X-ray detector | Low noise 816 mm line scan CCD, diode pitch 0.8 mm or 0.4 mm (optional) | |

| X-ray view | top down | |

| Cooling | Highly efficient, silent DC filter fans | |

| Housing finish | Stainless steel grade AISI 304 / DIN EN 1.4301 (X5CrNi18-10) | |

| Enclosure rating | IP54 (according to IEC 60529), including touch panel and fans | |

| Conveyor belt type | Polyurethane belt white, food grade | |

| Belt width | 800 mm | |

| Scanning width | 800 mm | |

| Conveyor speed | Conveyor speed by product, 0.05 to 0.98 m/sec (7 fixed speed steps) | |

| Max. product dimensions | width x height: 800 x 800 mm |

|

| Max. product weight | 50 kg total weight | |

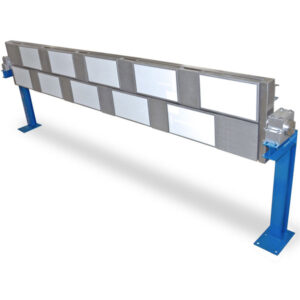

| Available reject method | Additional conveyor with transversal pusher | |

| Product memory | 255 different product set-ups | |

| Display | 17“ color-TFT capacitive touchscreen | |

| Inspection features | Autocalibration, auto adaption to density distribution, density, hard contrast, soft contrast, masking technology, SuperContrast, SizeFilter, AutoEdge masking, images AutoSave/Load, Multi Segment Inspection, metal can and foil inspection, fill quantity, generator energy by product, password protection | |

| In-/Outputs | Programmable outputs (contamination, ready, Emergency OFF) Programmable inputs (Emergency OFF, wake up, optional control signals) | |

| Data Transfer | Ethernet for remote support via internet, USB for external keyboard/ mouse/ memory stick | |

| Weight | 1.7 t | |

| Power supply | 1ph, 230 VAC +/- 10%, 50/60 Hz, 2.0 kW full operation | |

| Compressed air supply | without pusher 0 (zero) bar/psi with optional pusher system minimum 4 bar/58 psi |

|

| Environmental conditions | 0° to +30°C / 32°F to 86°F, with relative humidity max 90%, non-condensing, external cooling device recommendend/needed |

|

| Conformity | CE, compliant to german x-ray regulations, specific adaptation for other countries | |

Đánh giá

Chưa có đánh giá nào.