METAL DETECTION FOR TEXTILES, FLEECE AND WEBS METAL SHARK® FL & FL compact

[button link=”https://drive.google.com/file/d/1pS1Pxrb6doSbkfP_j2Ie7mXJ7N1TkrxH/view?usp=sharing” target=”_blank” color=”default” shape=”rounded” size=”small” align=”left”]CATALOG[/button]

Reliably detects magnetic and non-magnetic metals in fabrics and webs

Particularly flat for optimal approach to ascending or descending product paths, FL compact additionally rotatable

Highest sensitivity with 4-quadrant technology

Intuitive control and easy installation with autocalibration and TeachAssistant

Maintenance-free with automatic balance and calibration control

Features

Maximum detection performance with highest reliability in the entire detection area due to 4-quadrant technology

Simple setup with TeachAssistant

Memory for up to 250 products

Easy to use with intuitive and multilingual menus

4-level password system, automatic log out after time lapse

Documentation of all events and metal messages

IFS and HACCP reports easily available on the display at the touch of a button

Cyclical function monitoring with Performance Validation System (PVS)

Optionally: Data transfer to USB interface or connection to the company net-work via SHARKNET® softwareFunction

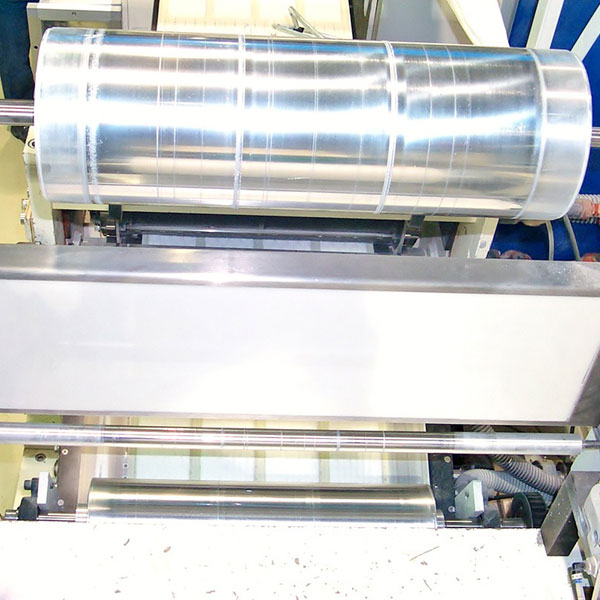

The METAL SHARK® FL and FL compact metal detectors are usually used for the inspection of nonwovens, textiles and films.

Both detectors are particularly flat and available in widths of 1,000 – 4,000 mm. The FL compact is rotatably mounted so that it can also be adapted to sloping webs.

Due to the high sensitivity of the FL models, tiny magnetic and non-magnetic metal particles (e.g. iron, aluminium and stainless steel) are detected over the entire width.

Specifications

| Electronics | Digital signal processor, noise filter, digital balance control, digital frequency control, PowerDrive circuit |

| Input | 2 analogue 0…10 V DC (option: 4-20 mA) 8 freely configurable 24 V DC signals, e.g. for encoders, product recognition, buttons |

| Output | 2 floating: “error” and “metal” 8 freely configurable 24 V DC signals |

| Inspection method | High-frequency magnetic field, multi-channel operation, balanced receiver coils |

| Metal detection | Ferrous, non-ferrous (e.g. aluminium, lead etc.) and stainless steel |

| Product compensation | 250 memory locations, automatic product compensation, with TeachAssistant |

| Enclosure rating | Controller IP65, sensor IP54 (optionally IP66) |

| Environmental conditions | Controller: -20°C to +40°C / -4°F to +104°F, optionally to -40°C / -40°F or +55°C / 131°F, rel. humidity 20% to 90% (non-condensing) Sensor: -30°C to +60°C / -22°F to 140°F, optionally up to +90°C / 194°F |

| Temperature of goods inspected | Standard: -30°C to +40°C /-22°F to +104°F Optionally: -40°C to +60°C / -40°F to 140°F |

| Power Supply | 1 phase 110-230 V AC +/- 5%, 20 W typ. (60 W max.) |

| Interface | RS232, LAN (optional, for SHARKNET®), USB (optional) |

| Maintenance | Maintenance-free, sensors calibrate themselves |

| Diagnostics | Integrated diagnostic software, automatic self-test |

| SHARKNET® | The SHARKNET® software connects METAL SHARK® metal detectors with a central computer, providing centralized storage of all operating data plus batch and alarm documentation for HACCP and IFS compliance. |

| LPW/HPW | Increase of the IP protection class by adapting the sensor seal, installing additional seals and a double housing for the control electronics |

| Temperature extension cold | Temperature range extended to -40°C (-40° F) Resin seals remain elastic at low temperatures. Special insulation, heated enclosure and other features. |

| Temperature extension hot | Temperature range extended to +55° C, (+131° F) Adapted enclosure, additional thermal insulation, replaceable filter fan, heat exchanger and/or active cooling units. |

| High temperature extension for product | Goods temperature up to +120°C (248° F) max. This option provides IP54 grade enclosure for the sensor. |

| Signalling devices (optical/acoustic) | Stacking lights and signal horns/sirens available in different versions and IP protection classes |

Sản phẩm tương tự

[button link=”https://drive.google.com/file/d/1CfN0n6N2gAYLPOIjpp5Q_ZFbII4yZMu7/view?usp=sharing” target=”_blank” color=”default” shape=”rounded” size=”small” align=”left”]CATALOG[/button]

Reliably detects metals in packaged and unpackaged products on conveyor belts

Removable sides make it particularly easy to install, ideal for conveyors that cannot be split

Highest sensitivity with 4-quadrant technology

Autocalibration and TeachAssistant for intuitive control and easy setup

Maintenance-free due to automatic balance and calibration control

Function

Metal detector METAL SHARK® TU is used in combination with conveyor belts or chutes when they cannot be divided or dismantled. The sidewalls of the TU can be removed so that the sensor plates can be easily pushed over and under the belt.

Thanks to its 4-quadrant technology, it detects magnetic and non-magnetic metal contaminants (iron, stainless steel, aluminum etc.) precisely and reliably. The robust stainless steel housing is easy to clean and robust and therefore suitable for many industries.

Reliably detects metals in free-falling goods

Simple assembly due to mounting frame and quick release rings

Highest sensitivity with 4-quadrant technology

Autocalibration and TeachAssistant for intuitive control and easy installation

Maintenance-free through automatic balance and calibration control

ATEX-version for use in explosion endangered environments

BRC-Kit option: Conformity with the Global Standard of the British Retail Consortium (BRC) for food safety

Function

The METAL SHARK® GF (Gravity Feed) is used for pipelines with free-falling products to detect metal contamination in continuously flowing granulates or powders such as sugar, flour, grain or even plastic granules.

The sensitive sensors detect the smallest metal contaminants, and fast-switching separation flaps discharge them directly from the product stream during ongoing production.

[button link=”https://drive.google.com/file/d/1R13G-pezDuiVPu_ybIMzoqdrX2Sm22sP/view?usp=sharing” target=”_blank” color=”default” shape=”rounded” size=”small” align=”left”]CATALOG[/button]

Reliably detects metals in raw or frozen meat in standardized E2 boxes

Especially high sensitivity with moist or frozen products with 3D detection

Easy setup and intuitive operation with Autocalibration and TeachAssistant

Maintenance-free design with automatic and continuous calibration of detector coils

BRC-Kit option: Conformity with the Global Standard of the British Retail Consortium (BRC) for food safety

[button link=”https://drive.google.com/file/d/1bBkhV_C-vhNjbp-rabXpgRCy89qEuv9v/view?usp=sharing” target=”_blank” color=”default” shape=”rounded” size=”small” align=”left”CATALOG[/button]

X-ray inspection for packaged food or non-food products

Detects high density materials like metal, ceramic, stone or plastic

Easy operation with autocalibration and clearly arranged functions on 17“ touchscreen

XIA software for instant analysis and detection with high accuracy and reliability

Quick release conveyor belt for easy cleaning and maintenance

Features

Real time detection with coloured contamination analysis

Functions for masking of product parts for better detection of contamination

Autosaving of inspection data with time and date stamp

User-friendly operation in daily business with 255 pre-set products

USB and Ethernet for data transfer

Quick release conveyor belt

Easy maintenance and cleaning

Built-in remote control and maintenance

24 hours non-stop operation

TÜV-approved: reliable safety standard, certificate optional

Function

The XRAY SHARK® XD28-L1 is particularly suitable for packaged food or non-food products, for example in plastic packaging, jars, cartons and even metal foil or metal cans. Unwanted foreign objects such as metal, stones, ceramics or plastic with high density in the product are detected.

The hygienic design allows easy cleaning and maintenance of the device – without the need for tools. This makes the XD28-L1 particularly suitable for all companies and industries that have to ensure high hygiene standards (also available with IP66).Description

Undesired foreign bodies in food, pharmaceuticals or other non-food products are a major problem. If a metal detector does not suffice, CASSEL x-ray inspection systems are a perfect solution to preserve your products quality.

XRAY SHARK® XD28-L1 is particularly suitable for smaller, packaged food or non-food products contained in jars, boxes, plastic packaging and even metal foils or metal cans. It is CASSEL’s most compact x-ray device and therefore ideal for narrow production lines.

User-friendly operation:

XRAY SHARK® XD28-L1 has a large 17”color touch screen and intuitive software that is easy to use. No special training is needed to operate the x-ray device.

Easy cleaning and maintenance:

The XRAY SHARK® XD28-L1 hygienic design allows for easy cleaning and maintenance. With the conveyor’s quick release, the conveyor belt can be removed in five easy steps for cleaning. The x-ray protection curtains can be removed by just pushing one button. After cleaning the belt, the curtains can be replaced just as easily, and the device is then quickly ready to resume operation.

Real time detection with colored contamination analysis:

All CASSEL x-ray inspection systems provide maximum sensitivity in the detection of foreign bodies. On the touch screen of the x-ray device contamination is highlighted in red.

Masking functions:

The advanced XIA 3 software program omits certain parts of the product from inspection. This is particularly useful for packaged products, where the actual packaging should not be inspected for foreign bodies. The masking prevents unnecessary false rejection of products.

24 hour non-stop operation:

High-quality components and the most advanced technology allow non-stop operation, 24 hours a day, 7 days a week.

Reliable German safety standards – TÜV-certificate on demand:

The flawless design offers maximum safety and comfort for daily operating. The radiation leakage rate is only max. 1 µSv / h or less.

Ethernet and USB:

Connect our x-ray inspection system to your network. CASSEL provides all X-ray machines with USB and Ethernet interfaces as a standard.

Auto storing of inspection data, with time/date stamp:

All data can be saved for quality control. The XRAY SHARK® XD28-L1 has an automatic memory function. The option of storing data only for contaminated products is also available. All data is provided with a time and date stamp. You can easily check this data and analyze it.

Built-in remote maintenance:

If on-site technicians are not available, CASSEL x-ray inspection systems have a built-in remote maintenance function. Our qualified service engineers will help you with any questions, no matter where your x-ray machine is located. That way, expensive travel costs can be saved and quick solutions can be found.

Đánh giá

Chưa có đánh giá nào.