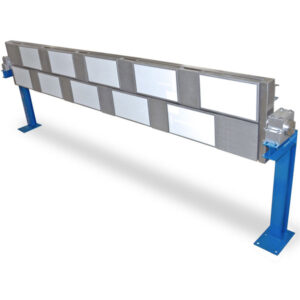

PROTECTION FOR CRUSHERS, GRINDERS AND OTHER MACHINES Metal detector PSQ RA

[button link=”https://drive.google.com/file/d/1_EXMQDEljiovgIMGoaCQUl6KlE7G9Jp9/view?usp=sharing” target=”_blank” color=”default” shape=”rounded” size=”small” align=”left”]CATALOG[/button]

Extremly resistant to weather, dirt or impact of stones and also immune to vibration

Simple and timesaving mounting: belt must not be devided due to a devidable probe

Can be used in the proximitry of frequency converters

Low difference in sensitivity on different sensing heights above the belt

CE-certified

Features

Average sensitivity (from M40 nuts)

Nearly homogeneous sensitivity on the belt and in the upper layers of the product

Can be used close to frequency converters, only 1 m minimum distance between probe and motors or magnets

Passage widths from 1 m to 2.4 m and heights can be adjusted as required

Extremely robust design

Very simple operation

Monitoring and display of internal parameters. (Helpful when calling for telephone support)

Function

The PSQ RA series of metal detector (opterating with a frame-probe) detects all kinds of metal, which means not only iron, but also aluminium, stainless steel, copper or mild steel.

The specialty of this detector is a low difference between edge and center of probe aperture. Therefore it is especially suitable if the depth of burden on the belt is more tan 600 mm. It’s frame can be devided and easily be built around the belt.

This metal detector prevents damage, avoids downtimes and produces significant savings on repair costs.

Specifications

| Electronics | digital signal processor, noise filter, digital balance control, digital frequency control, PowerDrive circuit |

| Input Signals | 1 coaxial cable, probe |

| Output Signals | Metal alarm: 1 relais with 2 floating changeover contacts, switching capacity 230 V 5 A resistive load, switchable between normally relaxed or normally activated mode Fault signal: 1 relais with 2 floating changeover contacts, switching capacity 230 V, 5 A resistive mode |

| Metal Detection | Iron, non-ferrous (e.g. aluminium or copper) und stainless steel |

| Belt widths | 1000 – 2400 mm |

| Protection Type | Control box: IP 55 Frame probe: IP76 |

| Ambience | Control box: -20° C up to +55° C Frame probe: for execution PE up to +60° C, for execution PA6.6 up to +120° C |

| Power Supply | 110-230 V, 50/60 Hz, typ. comsumption 15 VA |

| Material | Control box: steel or stainless steel, grey RAL 7032, electrophoretic dipcoating Frame probe: stainless u-structure steel Support for mounting: PE or PA6.66 |

Sản phẩm tương tự

[button link=”https://drive.google.com/file/d/1KXBB8MSTfUeJ03Adm2a0ps0MV1qjOfdb/view?usp=sharing” target=”_blank” color=”default” shape=”rounded” size=”small” align=”left”]CATALOG[/button]

Reliably detects metal contaminants in sausage meat and pâtés

Easy to integrate into all common piping systems

Stainless steel housing and frame are easy to clean, product pipe is CIP-compatible (Cleaning In Place)

Highest sensitivity through 4-quadrant technology

Intuitive operation, auto-calibration and TeachAssistant

FDA compliant

IN Meat is used with clippers, for twist off devices please use METAL SHARK® INA Meat

Function

Compact metal detector for sausage filling machines with mobile base frame on wheels. The stand with integrated gas spring offers easy height adjustment from 85-115 cm height.

The METAL SHARK® IN Meat is placed between filler and clip machine and can be delivered with or without ejection unit.

The unit is easy to clean and complies with FDA standards.

[button link=”https://drive.google.com/file/d/18_DGS4a1ycGbmUVWt3pCA7VU7cg_NZ39/view?usp=sharing” target=”_blank” color=”default” shape=”rounded” size=”small” align=”left”]CATALOG[/button]

Precise metal detection due to multi-segment sensor for particularly flat products

Highest sensitivity through 4-quadrant technology

Rotating sensor traverse adapts perfectly even to vertical or inclined product flow

Freely selectable widths up to 7 m and more

Intuitive control and easy installation with auto-calibration and TeachAssistant

Maintenance-free due to automatic balance and calibration control

Features

Maximum inspection performance with highest reliability in the entire detection area due to 4-quadrant technology

Simple setup with TeachAssistant

Memory for up to 250 products

Easy to use with intuitive and multilingual menus

4-level password system, automatic log out after time lapse

Detects iron from 0.5 mm and stainless steel from 0.9 mm with its position in a defined area of the fabric

Documentation of all events and metal messages

Optional: Data transfer to USB interface or connection to the company network via SHARKNET® software

Cyclical function monitoring with Performance Validation System (PVS)

Function

The METAL SHARK® COMBI is a rotatable multi-segment sensor that is typically used over very flat products such as fiber wood, plastic boards, fabric or nonwoven, paper or plastic webs.

It detects the smallest metal particles from 0.5 mm and locates their position in defined segments of the fabric.

The METAL SHARK® COMBI is available for widths up to 7,000 mm and more. It can also be operated without problems in humid workplaces with ambient temperatures from -10˚C to +40˚C and product temperatures up to 90°C.

Accessories & Extras

The METAL SHARK® COMBI can be perfectly adapted to your production by various special designs and accessories. Different numbers of sensor plates and widths um to 7,000 mm are possible as well as swiveling traverse arms or an adjustable travrse height.

For your audit reliability, a Performance Verification Certificate can be issued by CASSEL service technicians during commissioning or maintenance.

[button link=”https://drive.google.com/file/d/1sv7Lc5iq67BWyie6fm4VeOwYEc1Sxboo/view?usp=sharing” target=”_blank” color=”default” shape=”rounded” size=”small” align=”left”]CATALOG[/button]

Reliably detects metals in packaged and unpackaged products on conveyor belts

High sensitivity in dry, moist, salty or frozen goods with 3D detection

Easy setup and intuitive operation due to auto-calibration and TeachAssistant

Maintenance-free design with the automatic and continuous calibration of detector coils

BRC-Kit option: Conformity with the Global Standard of the British Retail Consortium (BRC) for food safety

Special models: UltraSens for even better sensitivity or Twinhead model to overcome orientation effects

[button link=”https://drive.google.com/file/d/1gaUf4cFS6nUZ-sBRvoTbIiyOUGSPR3Tg/view?usp=sharing” target=”_blank” color=”default” shape=”rounded” size=”small” align=”left”]CATALOG[/button]

Reliably detects metal contaminants in tablets and capsules

IQ, OQ, PQ qualification certificates are delivered directly, SQ also possible on request

Ejection with pendulum bell ensures that products are not damaged or jammed

Mobile and height adjustable, dismountable without tools for cleaning

Intuitive control, autocalibration and Teach Assistant

Features

Maximum detection performance with highest reliability in the entire detection area due to 4-quadrant technology

Simple setup with Teach Assistant

Memory spaces for up to 250 products

Easy to use with intuitive and multilingual menus

4-level password system, automatic log out after time lapse

Documentation of all events and metal messages

IFS and HACCP reports available on the display at the touch of a button

Optional: Data transfer to USB interface or connection to the company network via SHARKNET® software

Cyclical function monitoring with Performance Validation System (PVS)

Function

The METAL SHARK® PH is typically used at the outlet of tablet presses. It offers the highest metal sensitivity in detecting magnetic and non-magnetic metals.

The tablets fall through the metal detector. The ejection flap arranged downstream separates tablets with the smallest metal contaminants from the product stream.

The high-quality construction is maintenance-free. For cleaning, all parts in contact with the product can be disassembled without tools.

Đánh giá

Chưa có đánh giá nào.