METAL DETECTION FOR THE SAUSAGE INDUSTRY METAL SHARK® IN Meat

[button link=”https://drive.google.com/file/d/1KXBB8MSTfUeJ03Adm2a0ps0MV1qjOfdb/view?usp=sharing” target=”_blank” color=”default” shape=”rounded” size=”small” align=”left”]CATALOG[/button]

Reliably detects metal contaminants in sausage meat and pâtés

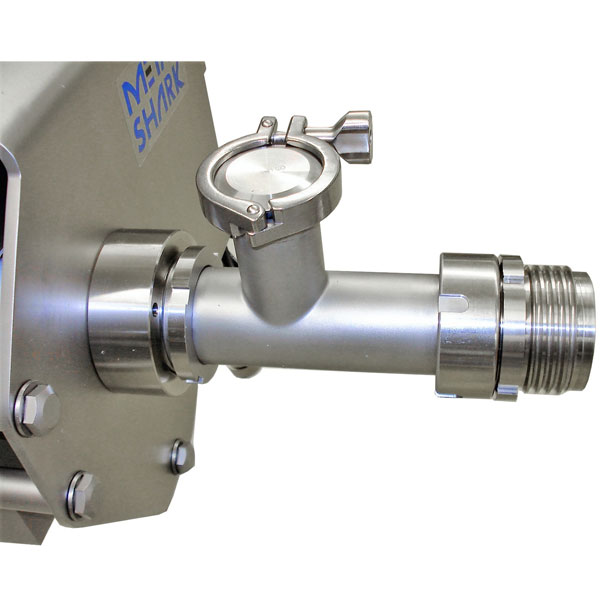

Easy to integrate into all common piping systems

Stainless steel housing and frame are easy to clean, product pipe is CIP-compatible (Cleaning In Place)

Highest sensitivity through 4-quadrant technology

Intuitive operation, auto-calibration and TeachAssistant

FDA compliant

IN Meat is used with clippers, for twist off devices please use METAL SHARK® INA Meat

Function

Compact metal detector for sausage filling machines with mobile base frame on wheels. The stand with integrated gas spring offers easy height adjustment from 85-115 cm height.

The METAL SHARK® IN Meat is placed between filler and clip machine and can be delivered with or without ejection unit.

The unit is easy to clean and complies with FDA standards.

Specifications

| Model | IN Meat 0065 | IN Meat 0065 / EX-PWC | |

| Type | without reject unit | with automatic rejection (piston valve) | |

| Overall length | 490 mm | 690 mm | |

| Metal alarm | double sausage length | automatic rejection | |

| Reject time | — | 0.1 – 9.9 sec adjustable | |

| Air pressure | — | min. 5 bar | |

| Delivery pressure | max. 60 bar | max. 40 bar | |

| Frame | mobile on 4 castors, height adjustable from 80-120 cm, stainless steel | ||

| Sensitivity | laboratory: FE 0,5 mm, VA 0,8 mm with sausage meat: FE 1,0 – 1,5 mm, VA 2,0 – 2,5 mm |

||

| Electronics | Digital signal processor, noise filter, digital balance control, digital frequency control, PowerDrive circuit | ||

| Input Signals | 8 freely configurable 24 V DC signals, e.g. for reject confirmation | ||

| Output Signals | 2 potential-free: “Error” and “Metal” 8 freely configurable 24 V DC signals, e.g. for optic/acoustic alarm |

||

| Inspection Method | inductive, multi channel operation, balanced reciver colls | ||

| Metal Detection | Iron, non-ferrous (e.g. aluminium or copper) and stainless steel | ||

| Product Compensation | 250 memory spaces, product compensation is automatic | ||

| Protection Type | IP 68 / NEMA 6P (for daily hose cleaning in wet environments) | ||

| Ambience | standard: -10° C bis +40° C, rel. humidity 30% up to 80% (non-condensing) | ||

| Product Temperature | standard: -30° C to +40° C optional: -40° C to +60° C |

||

| Power Supply | One phase 85-264 VAC, 50/60 Hz, 100 W | ||

| Interface | RS232, provides documentation according to HACCP and IFS standard, USB- or ethernet option | ||

| Maintenance | maintenance-free, self-calibrating sensors | ||

| Diagnosis | integrated diagnostic software, automatic self-test | ||

| Air pressure monitoring | Reports an error if the pressure is too low for the functionality of the reject valve | ||

| Reject monitoring | End position sensing for the ejection cylinder, software module reports error if the ejection piston hangs, clip signal is suppressed | ||

| Testport | The inlet tube is equipped with a T-piece and a sealing cap for inserting the test ball. Tube is 230mm long instead of 160mm. The pipe pump must be stopped before the sealing cap is opened | ||

| Test balls | Test balls, diameter 10 mm made of plastic POM, with embedded metal ball made of iron, brass and stainless steel, certified Ball size, metal type and certificate number are embedded in the test ball | ||

| Test bars | made of white, flexible plastic, certified, with embedded metal ball made of iron, ball size / metal type engraved | ||

| SHARKNET® | The SHARKNET® software connects METAL SHARK® metal detectors to a central computer and offers central storage of all operating data as well as batch and alarm documentation for HACCP and IFS conformity. | ||

| Frame | more stable frame construction possible | ||

| Signalling devices (optical/acoustic) | |||

Sản phẩm tương tự

[button link=”https://drive.google.com/file/d/1gaUf4cFS6nUZ-sBRvoTbIiyOUGSPR3Tg/view?usp=sharing” target=”_blank” color=”default” shape=”rounded” size=”small” align=”left”]CATALOG[/button]

Reliably detects metal contaminants in tablets and capsules

IQ, OQ, PQ qualification certificates are delivered directly, SQ also possible on request

Ejection with pendulum bell ensures that products are not damaged or jammed

Mobile and height adjustable, dismountable without tools for cleaning

Intuitive control, autocalibration and Teach Assistant

Features

Maximum detection performance with highest reliability in the entire detection area due to 4-quadrant technology

Simple setup with Teach Assistant

Memory spaces for up to 250 products

Easy to use with intuitive and multilingual menus

4-level password system, automatic log out after time lapse

Documentation of all events and metal messages

IFS and HACCP reports available on the display at the touch of a button

Optional: Data transfer to USB interface or connection to the company network via SHARKNET® software

Cyclical function monitoring with Performance Validation System (PVS)

Function

The METAL SHARK® PH is typically used at the outlet of tablet presses. It offers the highest metal sensitivity in detecting magnetic and non-magnetic metals.

The tablets fall through the metal detector. The ejection flap arranged downstream separates tablets with the smallest metal contaminants from the product stream.

The high-quality construction is maintenance-free. For cleaning, all parts in contact with the product can be disassembled without tools.

[button link=”https://drive.google.com/file/d/1AKd8ERvxZCLhwYOpQy1yeVZF2EPBv6rl/view?usp=sharing” target=”_blank” color=”default” shape=”rounded” size=”small” align=”left”]CATALOG[/button]

Reliably finds metal contaminants in sausage meat

Easy to integrate into all common piping systems

Stainless steel housing and frame are robust and easy to clean – ideal for the meat industry

Highest sensitivity with 4-quadrant technology

Autocalibration and Teach Assistant for intuitive control and easy installation

for use with twist-off devices, for clippers please use the IN Meat

Features

Maximum detection performance with the highest reliability in the entire detection area due to 4-quadrant technology

Simple setup with Teach Assistant

Storage spaces for up to 250 products

Easy to use with intuitive and multilingual menus

4-level password system, automatic log out after time lapse

Easy to fit into common pipelines

CIP-fähig (Cleaning In Place)

Documentation of all events and metal messages

IFS and HACCP reports available on the display at the touch of a button

Optional: Data transfer to USB interface or connection to the company network via SHARKNET® software

Cyclical function monitoring with Performance Validation System (PVS)

Function

Compact metal detector for sausage filling machines and sausage meat with the mobile base frame on wheels. The stand with integrated gas spring offers easy height adjustment from 85 to 120 cm height.

The METAL SHARK® INA Meat can be used universally with twisting devices and automatic clip machines. In the twist-off mode, the foreign device cable is simply plugged into the foreign device socket on the filling machine. For automatic clip machines or automatic hanging lines, the foreign device cable is inserted into the existing cable between the filling machine and the clip or hanging machine. Plug and socket types are supplied to match the filling machine type.

The device is easy to clean and complies with the FDA standard.

[button link=”https://drive.google.com/file/d/1bBkhV_C-vhNjbp-rabXpgRCy89qEuv9v/view?usp=sharing” target=”_blank” color=”default” shape=”rounded” size=”small” align=”left”]CATALOG[/button]

X-ray inspection for packaged food or non-food products

Detects high density materials like metal, ceramic, stone or plastic

Easy operation with autocalibration and clearly arranged functions on 17“ touchscreen

XIA software for instant analysis and detection with high accuracy and reliability

Quick release conveyor belt for easy cleaning and maintenance

Features

Real time detection with coloured contamination analysis

Functions for masking of product parts for better detection of contamination

Autosaving of inspection data with time and date stamp

User-friendly operation in daily business with 255 pre-set products

USB and Ethernet for data transfer

Quick release conveyor belt

Easy maintenance and cleaning

Built-in remote control and maintenance

24 hours non-stop operation

TÜV-approved: reliable safety standard, TÜV certficate possible

Function

The XD38 is particularly suitable for packaged food or non-food products, for example in plastic packaging, jars, cartons and even metal foil or metal cans. Unwanted foreign objects such as metal, stones, ceramics or plastic with high density in the product are detected.

The hygienic design allows easy cleaning and maintenance of the device – without the need for tools. This makes the XD38 particularly suitable for all companies and industries that have to ensure high hygiene standards (also available with IP66).

Description

XRAY SHARK® XD38 is particularly suitable for smaller, packaged food or non-food products contained in jars, boxes, plastic packaging and even metal foils or metal cans. Undesirable contaminants such as metal, stone, ceramic, glass or plastic particles with high density can be detected in the product.

The large 17”color touch screen and intuitive software make it easy to use. No special training is needed to operate the x-ray device.

Easy cleaning and maintenance:

The hygienic design allows for easy cleaning and maintenance, without any tools. With the conveyor’s quick release, the conveyor belt can be removed in five easy steps for cleaning. The X-ray protection curtains can be removed by just pushing one button. After cleaning the belt, the curtains can be replaced just as easily, and the device is then quickly ready to resume operation.

Real time detection with colored contamination analysis:

CASSEL x-ray inspection systems provide maximum sensitivity in the detection of foreign bodies. Contaminated products are detected live and can be separated. On the touch screen of the X-ray device contamination is highlighted in red.

Masking functions:

The advanced XIA 3 software program omits certain parts of the product from inspection. This is particularly useful for packaged products, where the actual packaging should not be inspected for foreign bodies. The masking prevents unnecessary false rejection of products.

24 hour non-stop operation:

High-quality components and the advanced technology allow non-stop operation, 24 hours a day, 7 days a week.

Reliable German safety standards – TÜV-approved:

The flawless design offers maximum safety and comfort for daily operating. The radiation leakage rate is 1µSv/h respectively 3 µSv/h or less.

Ethernet and USB:

Connect our x-ray inspection system to your network. CASSEL provides all x-ray machines with USB and Ethernet interfaces as a standard.

Auto storing of inspection data, with time/date stamp:

All data can be stored for quality control. The x-ray machine XRAY SHARK® XD38 has an automatic memory function. The option of storing data only for contaminated products is also available. All data is provided with a time and date stamp. You can easily check this data and analyze it.

Built-in remote maintenance:

If on-site technicians are not available, CASSEL x-ray inspection systems have a built-in remote maintenance function. Our qualified service engineers will help you with any questions, no matter where your x-ray machine is located. That way, expensive travel costs can be saved and quick solutions can be found.

[button link=”https://drive.google.com/file/d/1_EXMQDEljiovgIMGoaCQUl6KlE7G9Jp9/view?usp=sharing” target=”_blank” color=”default” shape=”rounded” size=”small” align=”left”]CATALOG[/button]

Extremly resistant to weather, dirt or impact of stones and also immune to vibration

Simple and timesaving mounting: belt must not be devided due to a devidable probe

Can be used in the proximitry of frequency converters

Low difference in sensitivity on different sensing heights above the belt

CE-certified

Features

Average sensitivity (from M40 nuts)

Nearly homogeneous sensitivity on the belt and in the upper layers of the product

Can be used close to frequency converters, only 1 m minimum distance between probe and motors or magnets

Passage widths from 1 m to 2.4 m and heights can be adjusted as required

Extremely robust design

Very simple operation

Monitoring and display of internal parameters. (Helpful when calling for telephone support)

Function

The PSQ RA series of metal detector (opterating with a frame-probe) detects all kinds of metal, which means not only iron, but also aluminium, stainless steel, copper or mild steel.

The specialty of this detector is a low difference between edge and center of probe aperture. Therefore it is especially suitable if the depth of burden on the belt is more tan 600 mm. It’s frame can be devided and easily be built around the belt.

This metal detector prevents damage, avoids downtimes and produces significant savings on repair costs.

Đánh giá

Chưa có đánh giá nào.