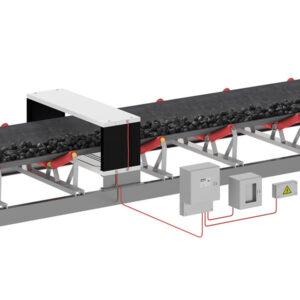

PROTECTION FOR CRUSHERS, GRINDERS AND OTHER MACHINES Metal detector PSQ RA

[button link=”https://drive.google.com/file/d/1_EXMQDEljiovgIMGoaCQUl6KlE7G9Jp9/view?usp=sharing” target=”_blank” color=”default” shape=”rounded” size=”small” align=”left”]CATALOG[/button]

Extremly resistant to weather, dirt or impact of stones and also immune to vibration

Simple and timesaving mounting: belt must not be devided due to a devidable probe

Can be used in the proximitry of frequency converters

Low difference in sensitivity on different sensing heights above the belt

CE-certified

Features

Average sensitivity (from M40 nuts)

Nearly homogeneous sensitivity on the belt and in the upper layers of the product

Can be used close to frequency converters, only 1 m minimum distance between probe and motors or magnets

Passage widths from 1 m to 2.4 m and heights can be adjusted as required

Extremely robust design

Very simple operation

Monitoring and display of internal parameters. (Helpful when calling for telephone support)

Function

The PSQ RA series of metal detector (opterating with a frame-probe) detects all kinds of metal, which means not only iron, but also aluminium, stainless steel, copper or mild steel.

The specialty of this detector is a low difference between edge and center of probe aperture. Therefore it is especially suitable if the depth of burden on the belt is more tan 600 mm. It’s frame can be devided and easily be built around the belt.

This metal detector prevents damage, avoids downtimes and produces significant savings on repair costs.

Specifications

| Electronics | digital signal processor, noise filter, digital balance control, digital frequency control, PowerDrive circuit |

| Input Signals | 1 coaxial cable, probe |

| Output Signals | Metal alarm: 1 relais with 2 floating changeover contacts, switching capacity 230 V 5 A resistive load, switchable between normally relaxed or normally activated mode Fault signal: 1 relais with 2 floating changeover contacts, switching capacity 230 V, 5 A resistive mode |

| Metal Detection | Iron, non-ferrous (e.g. aluminium or copper) und stainless steel |

| Belt widths | 1000 – 2400 mm |

| Protection Type | Control box: IP 55 Frame probe: IP76 |

| Ambience | Control box: -20° C up to +55° C Frame probe: for execution PE up to +60° C, for execution PA6.6 up to +120° C |

| Power Supply | 110-230 V, 50/60 Hz, typ. comsumption 15 VA |

| Material | Control box: steel or stainless steel, grey RAL 7032, electrophoretic dipcoating Frame probe: stainless u-structure steel Support for mounting: PE or PA6.66 |

Sản phẩm tương tự

[button link=”https://drive.google.com/file/d/1VsV1-_LD80DdyLconHkAk96eVwsQMIPo/view?usp=sharing” target=”_blank” color=”default” shape=”rounded” size=”small” align=”left”]CATALOG[/button]

Monitors bulk materials in the building materials industry or mining

Self-adjusting and extremely easy to install

High-quality components ensure reliability and long service life

Detects ferrous and non-ferrous metals, iron oxide and ore are ignored

Probe and amplifier are immune to vibration and resistant to weather, dirt and stone chips

Particularly robust and easy to clean

Features

Good sensitivity (M10 nuts) at belt speed of 0.3 – 6 m/s

Very simple operation

Can be used close to frequency conver-ters, only 2 m minimum distance between probe and motors or magnets

Belt widths from 500 mm to 2,000 mm

Monitoring and display of internal para-meters

Optional: Realization as tandem for higher debris heights

Optional: complete suppression of magnetite Fe3O4

Function

The QLC and QLCTA metal detectors offer good metal sensitivity for monitoring bulk materials in the mining and construction materials industry.

At a belt speed of 0.3 – 6.0 m/s they easily detect metal parts of the size of about M10 nuts and larger.

For higher sensitivity (M6 nuts) at a belt speed of max. 4.0 m/s we recommend the metal detectors SQ and SQTA.

[button link=”https://drive.google.com/file/d/1b7OBWPwwl17y7OM3o7M1bFgPnmPcKDH9/view?usp=sharing” target=”_blank” color=”default” shape=”rounded” size=”small” align=”left”]CATALOG[/button]

Specially designed for the monitoring of wood, fibre boards or any wide but thin product

AutoSens technology for automatic adjustment of the sensitivity to the mat height

Maintenance-free with automatic balance and calibration control

Durable aluminium design: particularly robust and easy to clean

Highest sensitivity with 4-quadrant technology

Autocalibration and Teach Assistant for intuitive control and easy installation

Features

Aperture widths from 1 m to 5 m as a standard (further sizes on request)

Maximum search performance with hig-hest reliability in the entire detection area due to 4-quadrant technology

Simple setup with TeachAssistant

Easy to use with intuitive and multilingu-al menus

Memory for up to 250 products

4-level password system, automatic log out after time lapse

Documentation of all events and metal messages

Optional: Data transfer to USB interface or connection to the company network via SHARKNET® software

Extended temperature range down to -40°C with specially adapted sensor and specially equipped control unit (option)

Cyclical function monitoring with Performance Validation System (PVS)

Function

The METAL SHARK® BIG pba with rectangular opening at a rather low opening height is especially designed for monitoring fibre mats, MDF, OSC or chipboard as well as other panel materials.

The typical installation takes place around a conveyor belt with flat belt.

Using 3D detection technology, it detects magnetic and non-magnetic metal contaminants (iron, stainless steel, aluminium etc.) precisely and reliably even under difficult conditions.

Accessories & Extras

The METAL SHARK® BIG pba can be perfectly adapted to your production with various special designs and accessories.

Different temperature requirements are taken into account as well as complicated product requirements for metal detection.

[button link=”https://drive.google.com/file/d/15w4V_2y1W2CO0PSFPNBXqUt865Q2KS0E/view?usp=sharing” target=”_blank” color=”default” shape=”rounded” size=”small” align=”left”]CATALOG[/button]

Optimally adapted to the monitoring of entire tree trunks

Sensor diameter up to 1.8 m (further sizes on request)

Sturdy stainless steel design: particularly robust and with short metal-free zone

Maintenance-free with automatic balance and calibration control

Sturdy stainless steel design: particularly robust and with short metal-free zone

Highest sensitivity with 4-quadrant technology

Intuitive control and easy installation with autocalibration and TeachAssistant

Features

Sensor diameter up to 1.8 m (further sizes on request)

Robust against environmental influences such as high and low temperatures

Maximum detection performance with highest reliability in the entire detection area due to 4-quadrant technology

Simple setup with TeachAssistant

Easy to use with intuitive and multilingual menus

Memory for up to 250 products

Maintenance-free with Autocalibration

Documentation of all events and metal messages

Optional: Data transfer to USB interface or connection to the company network via SHARKNET® software

Extended temperature range down to -40°C with specially adapted sensor and specially equipped control unit (option)

4-level password system, automatic log out after time lapse

Cyclical function monitoring with Performance Validation System (PVS)

Function

The METAL SHARK® OCTA has been developed for industrial applications in the timber industry and sawmills. It detects magnetic and non-magnetic metal contaminants (iron, tombac, brass, stainless steel, etc.) precisely and reliably even under difficult conditions.

The octagonal shape makes it ideal for monitoring logs for metal parts such as shrapnel, bullet fragments, nails, screws, etc.

It is typically installed in troughed conveyor belts.

Accessories & Extras

The METAL SHARK® OCTA can be perfectly adapted to your production by various special designs and accessories.

Different temperature requirements are taken into account as well as complicated product requirements for metal detection.

[button link=”https://drive.google.com/file/d/1bBkhV_C-vhNjbp-rabXpgRCy89qEuv9v/view?usp=sharing” target=”_blank” color=”default” shape=”rounded” size=”small” align=”left”CATALOG[/button]

X-ray inspection for packaged food or non-food products

Detects high density materials like metal, ceramic, stone or plastic

Easy operation with autocalibration and clearly arranged functions on 17“ touchscreen

XIA software for instant analysis and detection with high accuracy and reliability

Quick release conveyor belt for easy cleaning and maintenance

Features

Real time detection with coloured contamination analysis

Functions for masking of product parts for better detection of contamination

Autosaving of inspection data with time and date stamp

User-friendly operation in daily business with 255 pre-set products

USB and Ethernet for data transfer

Quick release conveyor belt

Easy maintenance and cleaning

Built-in remote control and maintenance

24 hours non-stop operation

TÜV-approved: reliable safety standard, certificate optional

Function

The XRAY SHARK® XD28-L1 is particularly suitable for packaged food or non-food products, for example in plastic packaging, jars, cartons and even metal foil or metal cans. Unwanted foreign objects such as metal, stones, ceramics or plastic with high density in the product are detected.

The hygienic design allows easy cleaning and maintenance of the device – without the need for tools. This makes the XD28-L1 particularly suitable for all companies and industries that have to ensure high hygiene standards (also available with IP66).Description

Undesired foreign bodies in food, pharmaceuticals or other non-food products are a major problem. If a metal detector does not suffice, CASSEL x-ray inspection systems are a perfect solution to preserve your products quality.

XRAY SHARK® XD28-L1 is particularly suitable for smaller, packaged food or non-food products contained in jars, boxes, plastic packaging and even metal foils or metal cans. It is CASSEL’s most compact x-ray device and therefore ideal for narrow production lines.

User-friendly operation:

XRAY SHARK® XD28-L1 has a large 17”color touch screen and intuitive software that is easy to use. No special training is needed to operate the x-ray device.

Easy cleaning and maintenance:

The XRAY SHARK® XD28-L1 hygienic design allows for easy cleaning and maintenance. With the conveyor’s quick release, the conveyor belt can be removed in five easy steps for cleaning. The x-ray protection curtains can be removed by just pushing one button. After cleaning the belt, the curtains can be replaced just as easily, and the device is then quickly ready to resume operation.

Real time detection with colored contamination analysis:

All CASSEL x-ray inspection systems provide maximum sensitivity in the detection of foreign bodies. On the touch screen of the x-ray device contamination is highlighted in red.

Masking functions:

The advanced XIA 3 software program omits certain parts of the product from inspection. This is particularly useful for packaged products, where the actual packaging should not be inspected for foreign bodies. The masking prevents unnecessary false rejection of products.

24 hour non-stop operation:

High-quality components and the most advanced technology allow non-stop operation, 24 hours a day, 7 days a week.

Reliable German safety standards – TÜV-certificate on demand:

The flawless design offers maximum safety and comfort for daily operating. The radiation leakage rate is only max. 1 µSv / h or less.

Ethernet and USB:

Connect our x-ray inspection system to your network. CASSEL provides all X-ray machines with USB and Ethernet interfaces as a standard.

Auto storing of inspection data, with time/date stamp:

All data can be saved for quality control. The XRAY SHARK® XD28-L1 has an automatic memory function. The option of storing data only for contaminated products is also available. All data is provided with a time and date stamp. You can easily check this data and analyze it.

Built-in remote maintenance:

If on-site technicians are not available, CASSEL x-ray inspection systems have a built-in remote maintenance function. Our qualified service engineers will help you with any questions, no matter where your x-ray machine is located. That way, expensive travel costs can be saved and quick solutions can be found.

Đánh giá

Chưa có đánh giá nào.